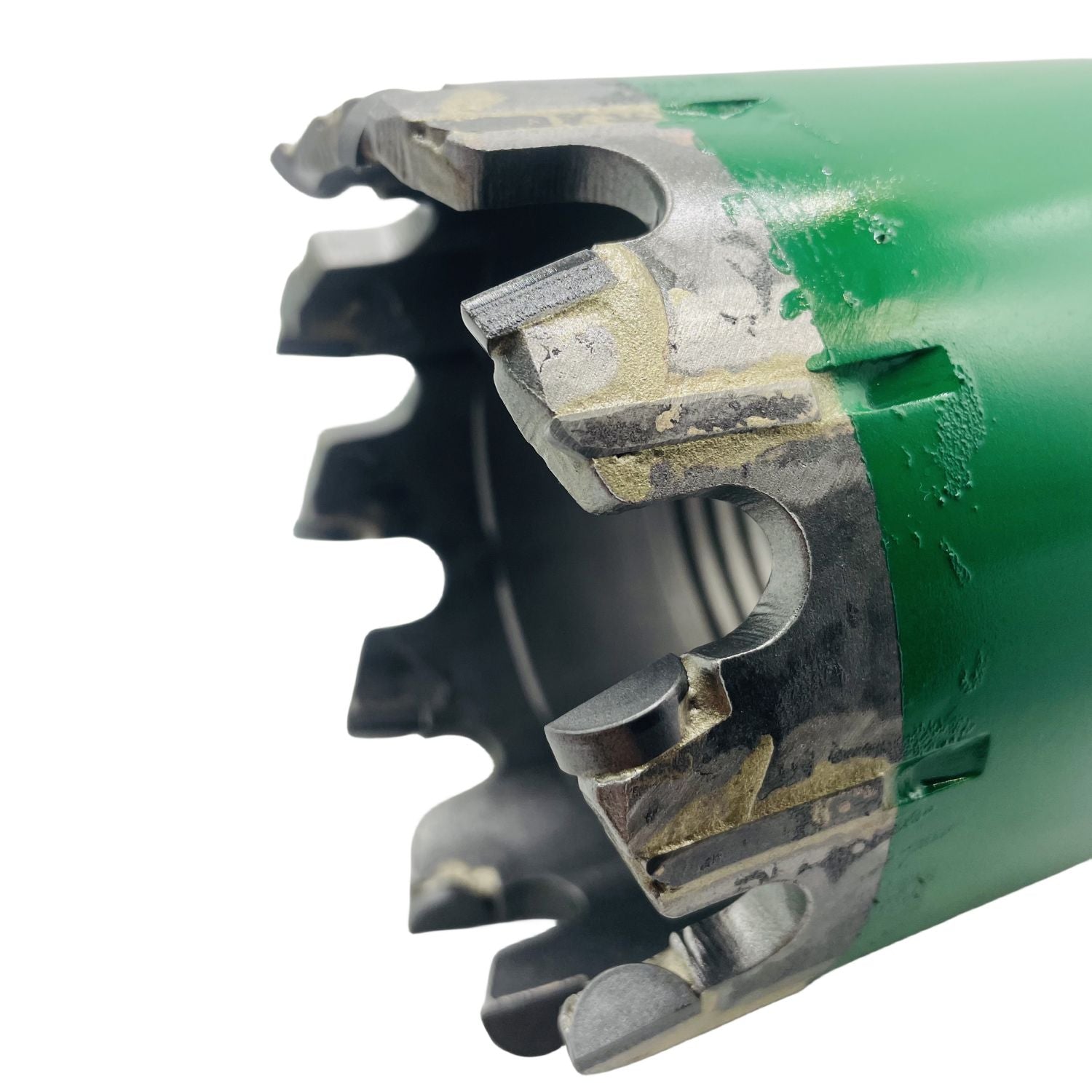

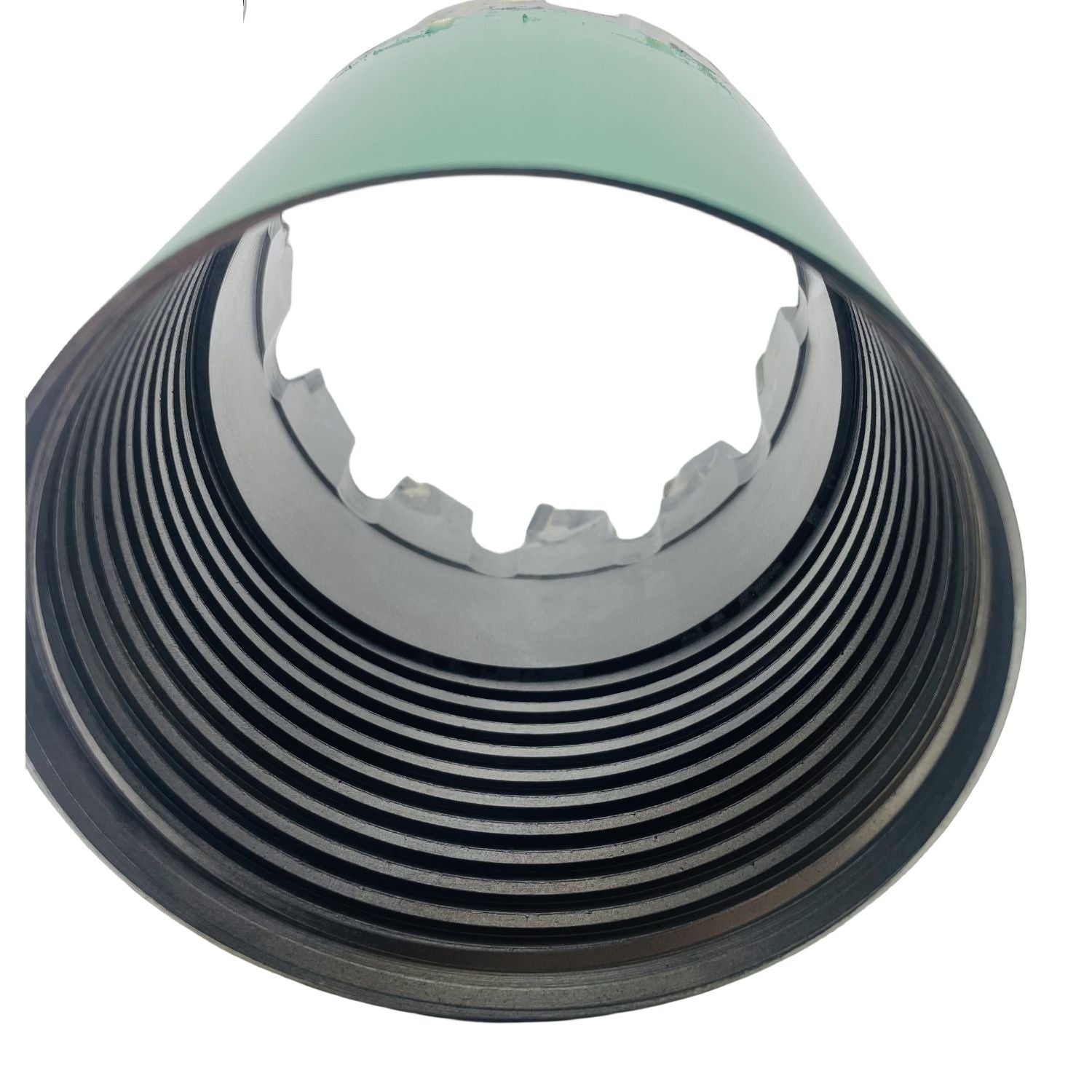

PDC Core Drill Bit with Blade Segments for Hard Rock and Granite

The PDC Core Drill Bit with Blade Segments is designed for precision drilling in hard rock and granite. Featuring durable polycrystalline diamond material and blade segments, this drill bit reduces...

Our Craftsmanship

| Model | ** |

|---|---|

| Brand | FENGSU |

| Type | Drill bit |

| Material | Aolly |

| Size Range | ** |

| Thread Type | ** |

| Recommended Formation | ** |

| Origin | HUNAN,China |

| Packaging | Carton or Wooden Box |

Comprehensive Rock Drilling Reference Table

| Stratum Classification/Name | Representing Rock Strata | Theoretical Drilling Speed/Recommended Pull-out Length | Recommended Drill Bits |

|---|---|---|---|

| Level 1 (Loose Soil) | Secondary loess, secondary Hongshi, soft sand without gravel and angular gravel, diatomaceous earth | 15M/h, 15M/P | Alloy drill bit, small-tooth composite drill bit, ordinary composite drill bit |

| Level 2 (Loose Rock) | Huangshi/Hongshi/Peaty Clay/Sandy Soil/Kaolin Type | 8M/h, 2.4M/P | Alloy drill bit, small-tooth composite drill bit, ordinary composite drill bit |

| Level 3 (Soft Rock) | Strongly Weathered Shale/Slate/Grazing Rock/Schist/Slightly Cemented Sand Layer | 6M/h, 2M/P | Ordinary composite drill bit, triangle composite drill bit, bread-shaped composite drill bit, blade-shaped composite drill bit |

| Level 4 (Slightly Soft Rock) | Shale, sandy shale, oil shale, carbonaceous shale, calcareous shale, sand shale interlayer, argillaceous limestone | 5M/h, 1.7M/P | Ordinary composite drill bit, triangle composite drill bit, bread-shaped composite drill bit, blade-shaped composite drill bit |

| Level 5 (Slightly Hard Rock) | Gravel and gravel layers, collapse layer muddy slate, sericite chlorite greenstone slate, schist, limestone, marble | 3M/h, 11.50M/P | Ordinary composite drill bit, triangle composite drill bit, bread-shaped composite drill bit, blade-shaped composite drill bit |

| Level 6-7 (Medium Hard Rock) | Chlorite, mica, slate, Qianmu rock, schist, silicified limestone, calcite | 2M/h, 1.3M/P-1.1M/P | Blade-shaped composite drill bit, reinforced composite drill bit, helmet-tooth composite drill bit, high-grade electroplated diamond drill bit |

| Level 8-9 (Hard Rock) | Silicified mica rock, gneiss, basalt, diorite, pyroxenite, quartz Anshan porphyry | 1.2M/h, 0.3M/P-0.65M/P | Thickened composite drill bit, blade-shaped composite drill bit, helmet-tooth composite drill bit, conventional electroplated diamond drill bit, thermally stable polycrystalline diamond (TSP) drill bit |

| Level 10-11 (Very Hard Rock) | Granite, granodiorite, gneiss, rhyolite, quartzite | 0.8M/h, 0.5M/P-0.32M/P | Body sintered drill bit, low-degree electroplated diamond drill bit, thermally stable polycrystalline diamond (TSP) drill bit. |

| Level 12 (Extremely Hard Rock) | Quartzite, jasper, angle shale, corundum rock, quartz, flint, jasper | 0.3M/h, 0.16M/P | Body sintered drill bit, low-degree electroplated diamond drill bit, thermally stable polycrystalline diamond (TSP) drill bit. |

If you have any questions, you can contact us via online chat!

Chat With UsYou May Also Like

Example product title

- $1.00

- $1.00

- Unit price

- per

Example product title

- $1.00

- $1.00

- Unit price

- per

Example product title

- $1.00

- $1.00

- Unit price

- per

Example product title

- $1.00

- $1.00

- Unit price

- per

- Choosing a selection results in a full page refresh.