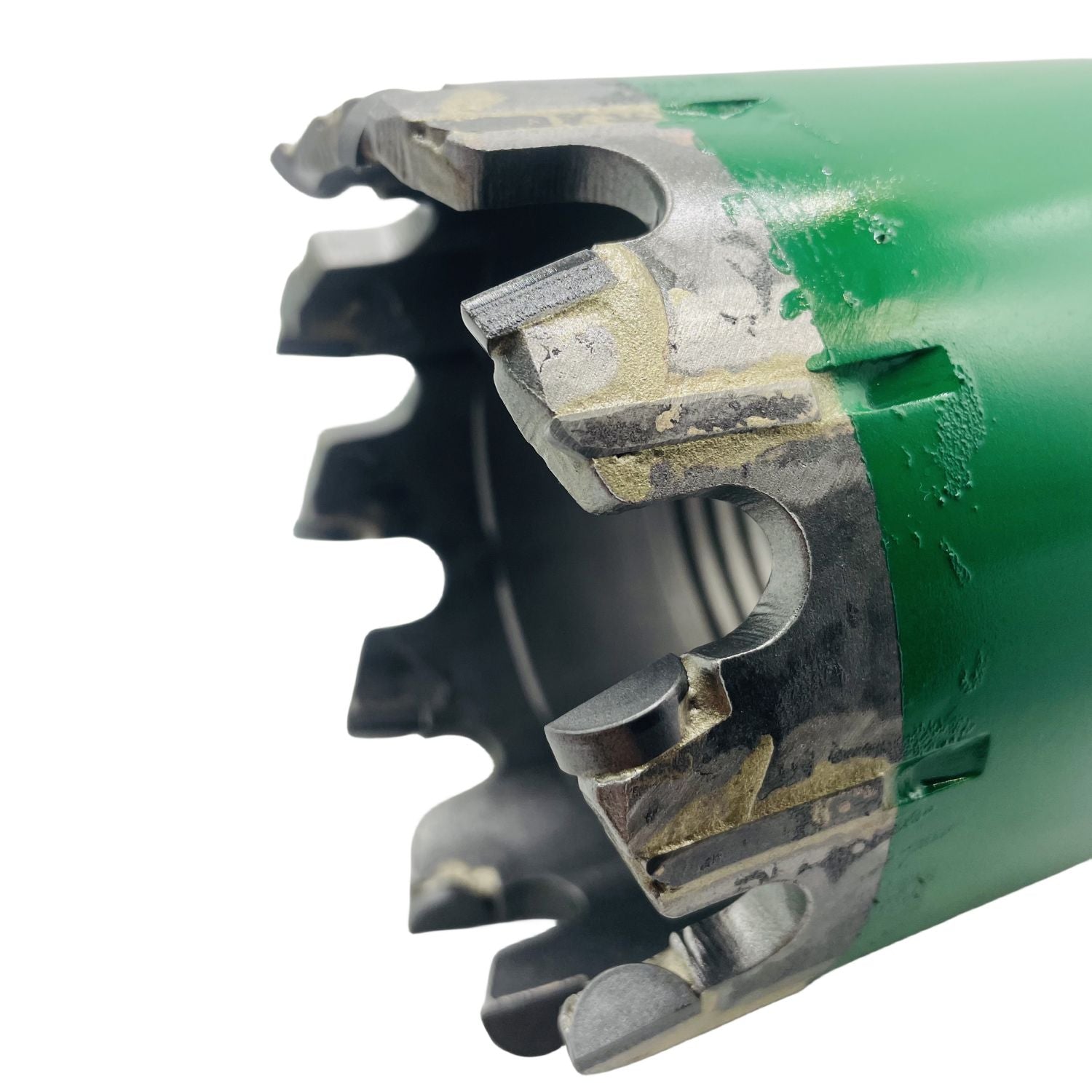

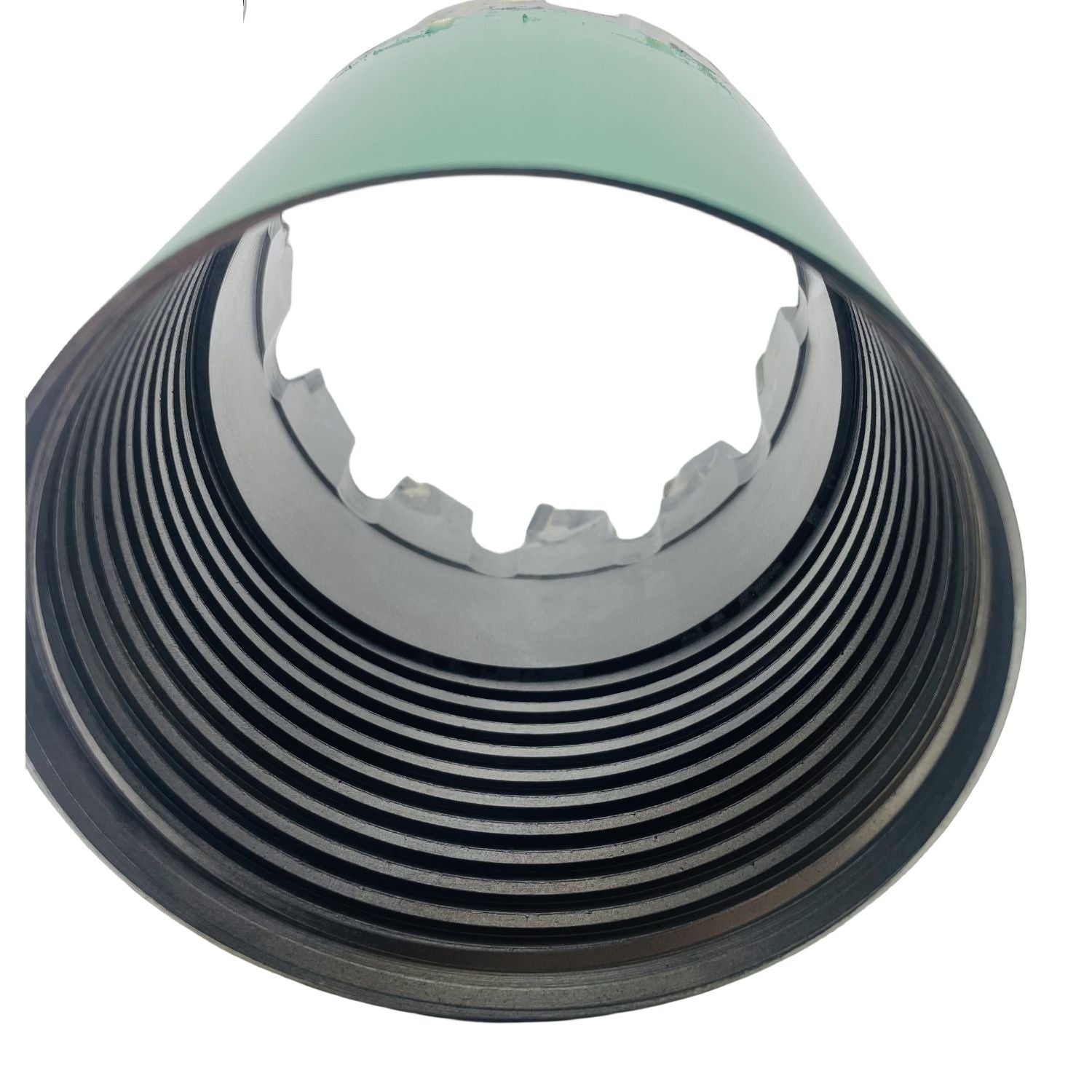

PDC Foret à noyau avec segments de lame pour roche dure et granit

Le PDC Foret à segments de lame est conçu pour le forage de précision dans la roche dure et le granit. Doté d'un matériau en diamant polycristallin durable et de...

Notre savoir-faire

| Model | ** |

|---|---|

| Brand | FENGSU |

| Type | Drill bit |

| Material | Aolly |

| Size Range | ** |

| Thread Type | ** |

| Recommended Formation | ** |

| Origin | HUNAN,China |

| Packaging | Carton or Wooden Box |

Tableau de référence complet sur le forage de roche

| Classification/Nom de la strate | Représenter les strates rocheuses | Vitesse de perçage théorique/longueur d'extraction recommandée | Forets recommandés |

|---|---|---|---|

| Niveau 1 (sol meuble) | Lœss secondaire, Hongshi secondaire, sable mou sans gravier et gravier angulaire, terre de diatomées | 15 M/h, 15 M/P | Foret en alliage, foret composite à petites dents, foret composite ordinaire |

| Niveau 2 (roche lâche) | Type Huangshi/Hongshi/Argile tourbeuse/Sableux/Kaolin | 8 M/h, 2,4 M/P | Foret en alliage, foret composite à petites dents, foret composite ordinaire |

| Niveau 3 (Soft Rock) | Schiste fortement altéré/ardoise/roche pâturée/schiste/couche de sable légèrement cimentée | 6 M/h, 2 M/P | Foret composite ordinaire, foret composite triangulaire, foret composite en forme de pain, foret composite en forme de lame |

| Niveau 4 (Légèrement Soft Rock) | Schiste, schiste sableux, schiste bitumineux, schiste carboné, schiste calcaire, couche intermédiaire de schiste sableux, calcaire argileux | 5 M/h, 1,7 M/P | Foret composite ordinaire, foret composite triangulaire, foret composite en forme de pain, foret composite en forme de lame |

| Niveau 5 (légèrement hard rock) | Couches de gravier et de gravier, couche d'effondrement d'ardoise boueuse, ardoise de pierre verte de chlorite de séricite, schiste, calcaire, marbre | 3 M/h, 11,50 M/P | Foret composite ordinaire, foret composite triangulaire, foret composite en forme de pain, foret composite en forme de lame |

| Niveau 6-7 (Moyen-Hard Rock) | Chlorite, mica, ardoise, roche Qianmu, schiste, calcaire silicifié, calcite | 2 M/h, 1,3 M/P-1,1 M/P | Foret composite en forme de lame, foret composite renforcé, foret composite à dents de casque, foret diamant électrolytique de haute qualité |

| Niveau 8-9 (Hard Rock) | Roche de mica silicifiée, gneiss, basalte, diorite, pyroxénite, quartz porphyre d'Anshan | 1,2 M/h, 0,3 M/P-0,65 M/P | Foret composite épaissi, foret composite en forme de lame, foret composite à dents de casque, foret diamant électrolytique conventionnel, foret diamant polycristallin (TSP) thermiquement stable |

| Niveau 10-11 (Très Hard Rock) | Granite, granodiorite, gneiss, rhyolite, quartzite | 0,8 M/h, 0,5 M/P-0,32 M/P | Foret fritté à corps, foret diamanté électrolytique à faible degré, foret diamant polycristallin (TSP) thermiquement stable. |

| Niveau 12 (extrêmement hard rock) | Quartzite, jaspe, schiste angulaire, corindon, quartz, silex, jaspe | 0,3 M/h, 0,16 M/P | Foret fritté à corps, foret diamanté électrolytique à faible degré, foret diamant polycristallin (TSP) thermiquement stable. |

Si vous avez des questions, vous pouvez nous contacter via le chat en ligne!

Discute avec nousTu pourrais aussi aimer

Titre de produit exemple

- $1.00

- $1.00

- Prix unitaire

- par

Titre de produit exemple

- $1.00

- $1.00

- Prix unitaire

- par

Titre de produit exemple

- $1.00

- $1.00

- Prix unitaire

- par

Titre de produit exemple

- $1.00

- $1.00

- Prix unitaire

- par

- Choisir une sélection entraîne un rafraîchissement complet de la page.