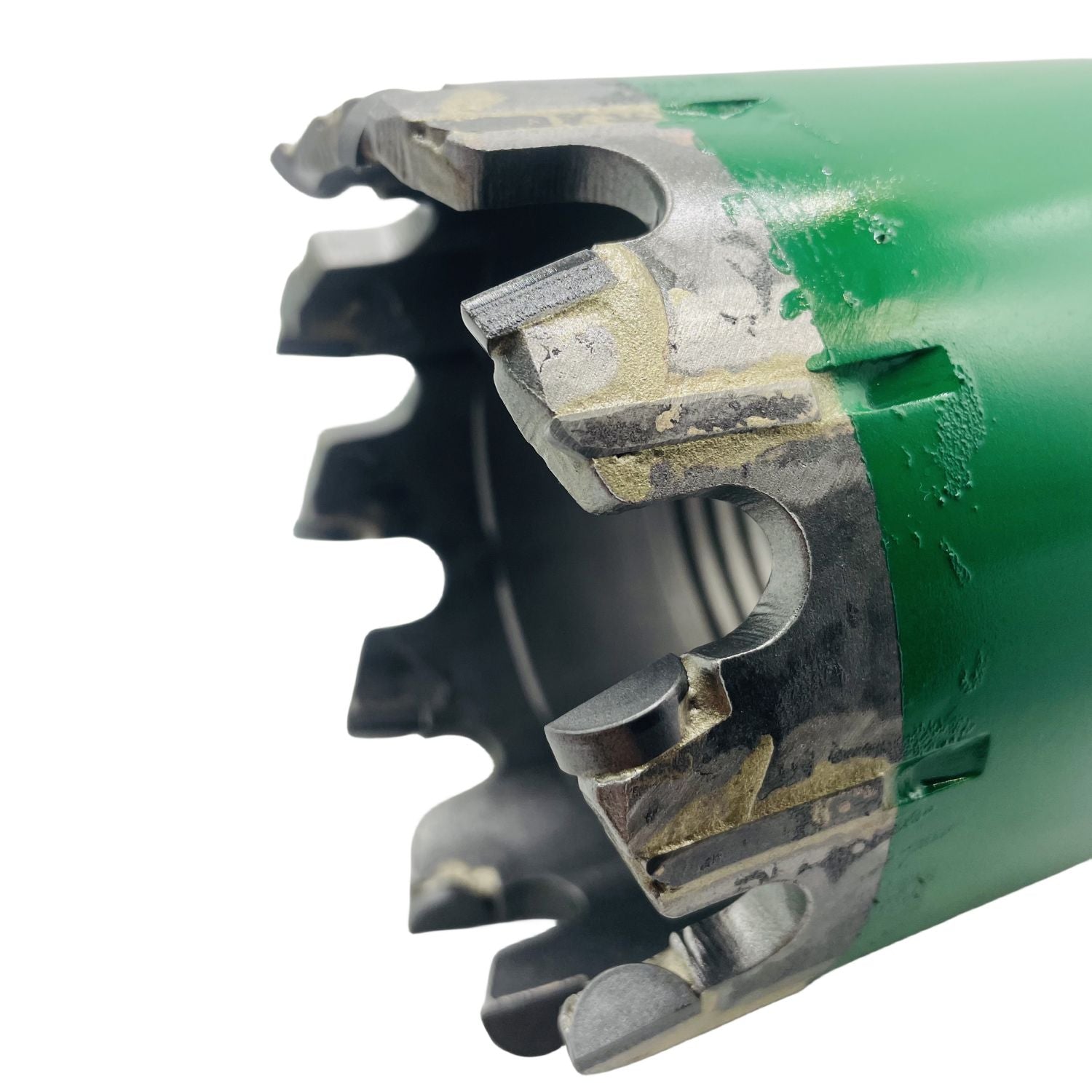

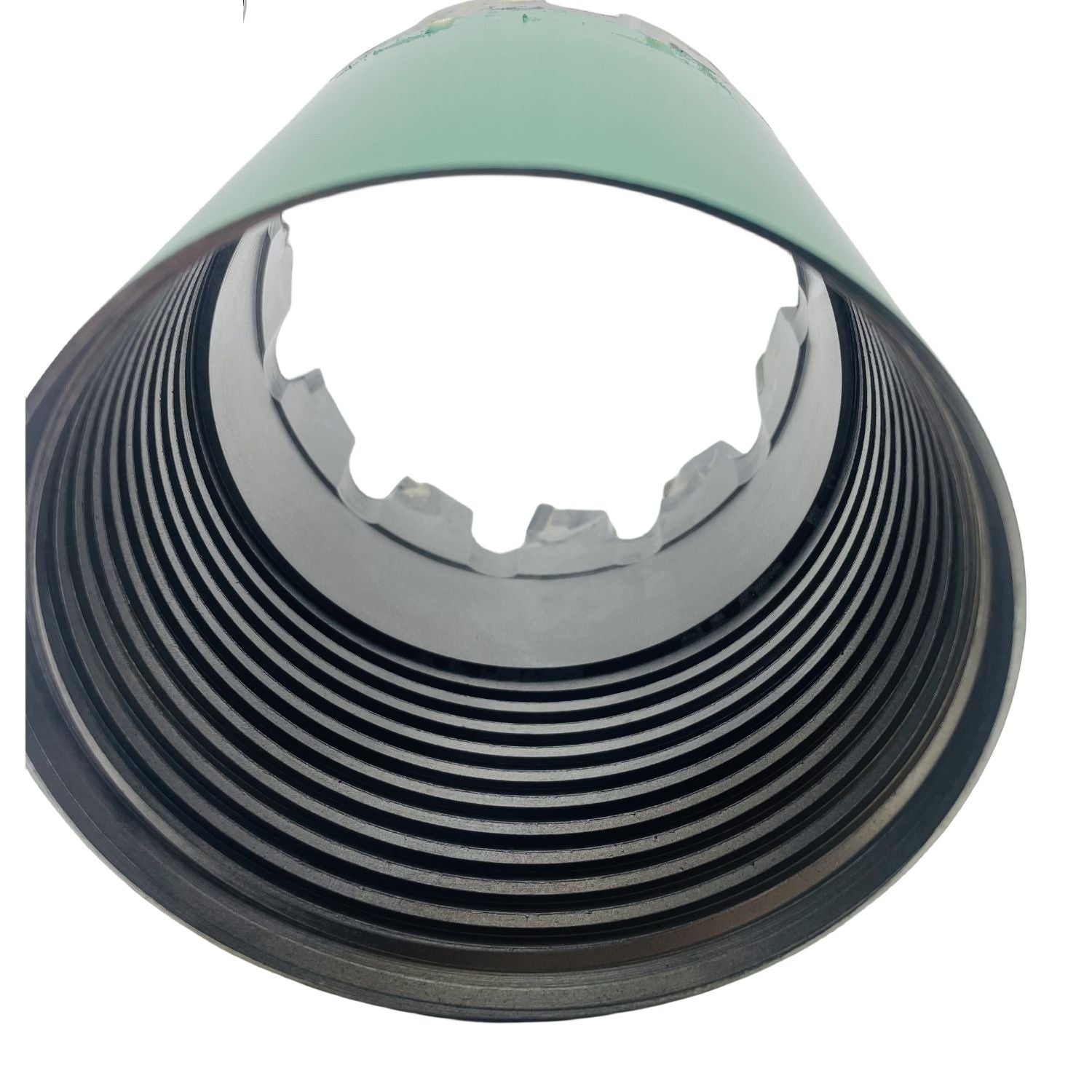

PDC Matattarar Rawar Ruwa tare da Yankunan Ruwan Wuka don Dutse Mai Wuya da Granite

Burin Core Drill Bit na PDC tare da Sassan Blade an ƙera shi don hakowa daidai a cikin dutsen mai wuya da granite. Tare da kayan polycrystalline diamond mai ɗorewa...

Sana'ar mu

| Model | ** |

|---|---|

| Brand | FENGSU |

| Type | Drill bit |

| Material | Aolly |

| Size Range | ** |

| Thread Type | ** |

| Recommended Formation | ** |

| Origin | HUNAN,China |

| Packaging | Carton or Wooden Box |

Cikakken Teburin Magana Hakowa

| Rarraba/Sunan Stratum | Wakilin Rock Strata | Gudun Hakowa Ka'idar/Shawarar Tsawon Fitarwa | Nasihar Drill Bits |

|---|---|---|---|

| Mataki na 1 (Ƙasa maras kyau) | Loess na sakandare, Hongshi na sakandare, yashi mai laushi maras tsakuwa da tsakuwa angular, ƙasa diatomaceous | 15M/h, 15M/P | Alloy drill bit, kananan-hakora hadaddiyar giyar bit, talakawa hadaddun rawar soja bit |

| Mataki na 2 (Loose Rock) | Huangshi/Hongshi/ Peaty Clay/Sandy Soil/Nau'in Kaolin | 8M/h, 2.4M/P | Alloy drill bit, kananan-hakora hadaddiyar giyar bit, talakawa hadaddun rawar soja bit |

| Mataki na 3 (Rock mai laushi) | Shale mai ƙarfi/Slate/Dutsen kiwo/Schist/Yashi mai Ciminti kaɗan | 6M/h, 2M/P | Matsakaicin haɗaɗɗen rawar jiki na yau da kullun, ɗanɗano mai haɗaɗɗun triangle, ɗanɗano mai siffa mai nau'in burodi, ɗanɗano mai siffar ruwa. |

| Mataki na 4 (Dutse mai laushi kaɗan) | Shale, yashi shale, mai shale, carbonaceous shale, calcareous shale, yashi shale interlayer, argillaceous limestone | 5M/h, 1.7M/P | Matsakaicin haɗaɗɗen rawar jiki na yau da kullun, ɗanɗano mai haɗaɗɗun triangle, ɗanɗano mai siffa mai nau'in burodi, ɗanɗano mai siffar ruwa. |

| Mataki na 5 (Dutsen Dan Tauri) | Tsakuwa da tsakuwa, rugujewar laka slate, sericite chlorite greenstone slate, schist, farar ƙasa, marmara | 3M/h, 11.50M/P | Matsakaicin haɗaɗɗen rawar jiki na yau da kullun, ɗanɗano mai haɗaɗɗun triangle, ɗanɗano mai siffa mai nau'in burodi, ɗanɗano mai siffar ruwa. |

| Mataki na 6-7 (Matsakaici Hard Rock) | Chlorite, mica, slate, Qianmu rock, schist, silicified limestone, calcite | 2M/h, 1.3M/P-1.1M/P | Ƙwaƙwalwar haƙori mai nau'in ruwa mai siffa, Ƙarfafa gwargwado na rawar soja, hular kwalkwali-haƙori hadadden rawar soja, babban ɗigon lu'u-lu'u mai ƙarfin lantarki |

| Mataki na 8-9 (Hard Rock) | Silicified mica rock, gneiss, basalt, diorite, pyroxenite, quartz Anshan porphyry | 1.2M/h, 0.3M/P-0.65M/P | Ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙwanƙwasa, ƙwanƙwasa-haƙori haɗaɗɗen rawar soja, bit ɗin lu'u-lu'u na al'ada na al'ada, kwanciyar hankali na polycrystalline lu'u-lu'u (TSP) rawar rawar soja. |

| Mataki na 10-11 (Rock mai tsananin gaske) | Granite, granodiorite, gneiss, rhyolite, quartzite | 0.8M/h, 0.5M/P-0.32M/P | Jikin rawar sojan da aka yi da shi, ƙaramin-digiri na lu'u-lu'u lu'u-lu'u rawar soja, madaidaicin zafin lu'u-lu'u polycrystalline (TSP). |

| Mataki na 12 (Tsarin Dutsen Dutse) | Quartzite, jasper, angle shale, corundum rock, ma'adini, flint, jasper | 0.3M/h, 0.16M/P | Jikin rawar sojan da aka yi da shi, ƙaramin-digiri na lu'u-lu'u lu'u-lu'u rawar soja, madaidaicin zafin lu'u-lu'u polycrystalline (TSP). |

Idan kuna da wasu tambayoyi, kuna iya tuntuɓar mu ta hanyar tattaunawa ta kan layi!

Yi Taɗi Da MuKuna iya So kuma

Misalin taken samfur

- $1.00

- $1.00

- Farashin kowane yanki

- ta kowanne

Misalin taken samfur

- $1.00

- $1.00

- Farashin kowane yanki

- ta kowanne

Misalin taken samfur

- $1.00

- $1.00

- Farashin kowane yanki

- ta kowanne

Misalin taken samfur

- $1.00

- $1.00

- Farashin kowane yanki

- ta kowanne

- Zaɓin zaɓi yana haifar da sabunta shafin gaba ɗaya.