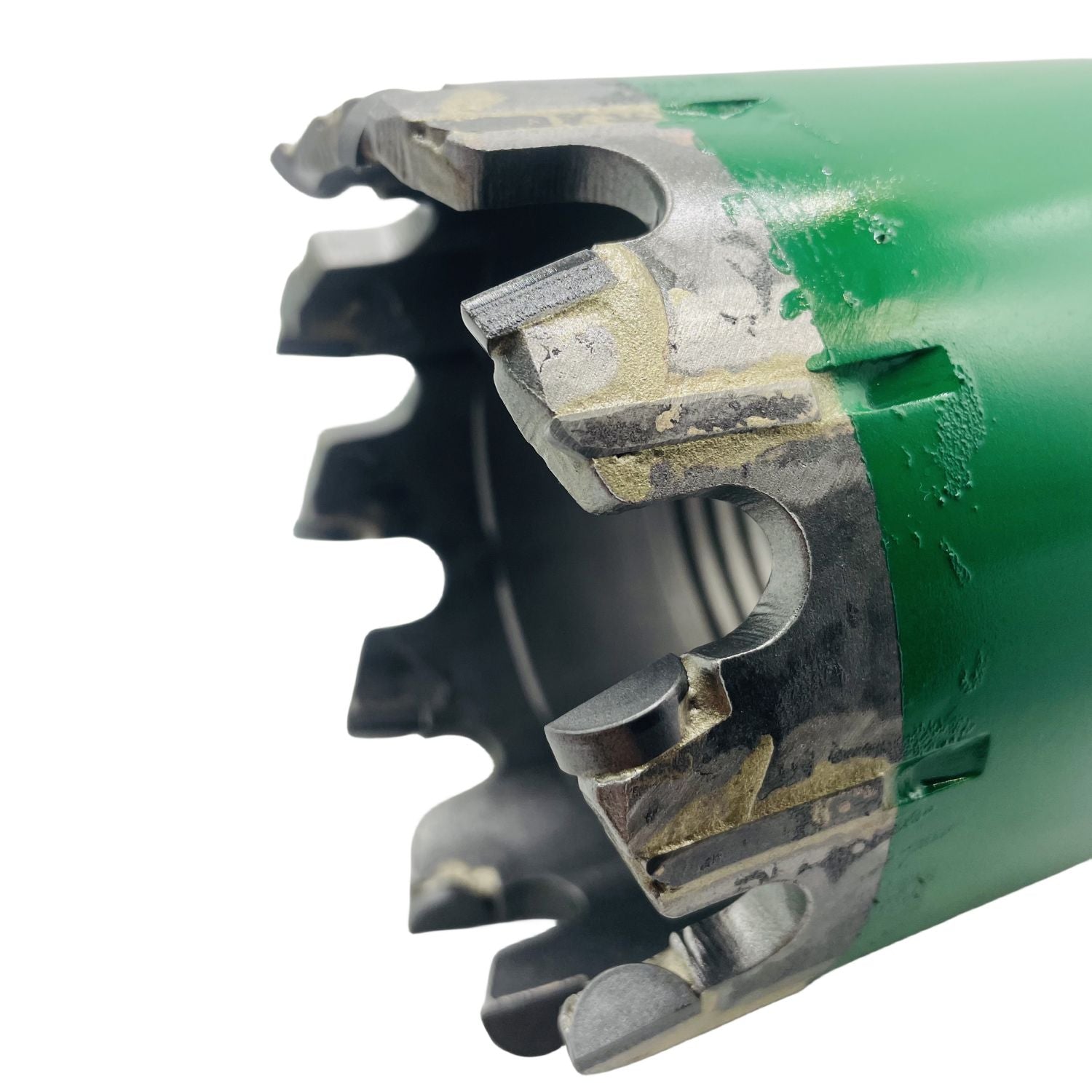

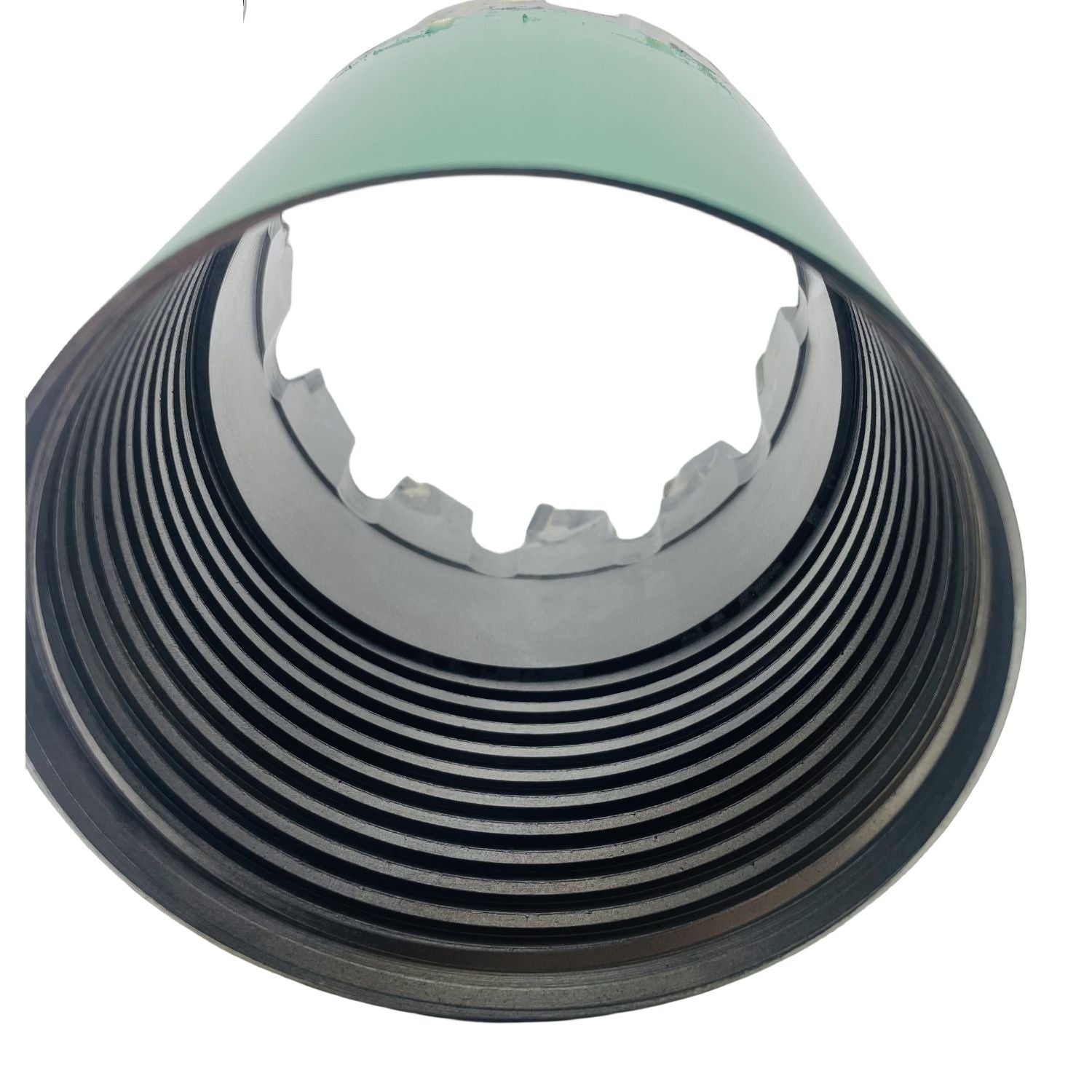

PDC Mata Bor Inti dengan Segmen Pisau untuk Batu Keras dan Granit

Mata Bor Inti PDC dengan Segmen Pisau dirancang untuk pengeboran presisi pada batu keras dan granit. Menampilkan bahan berlian polikristalin yang tahan lama dan segmen pisau, mata bor ini mengurangi...

Keahlian kami

| Model | ** |

|---|---|

| Brand | FENGSU |

| Type | Drill bit |

| Material | Aolly |

| Size Range | ** |

| Thread Type | ** |

| Recommended Formation | ** |

| Origin | HUNAN,China |

| Packaging | Carton or Wooden Box |

Tabel Referensi Pengeboran Batuan Komprehensif

| Klasifikasi/Nama Stratum | Mewakili Strata Batuan | Kecepatan Pengeboran Teoretis/Panjang Tarik yang Direkomendasikan | Mata Bor yang Direkomendasikan |

|---|---|---|---|

| Tingkat 1 (Tanah Gembur) | Loess sekunder, Hongshi sekunder, pasir lembut tanpa kerikil dan kerikil bersudut, tanah diatom | 15 juta/jam, 15 juta/p | Mata bor paduan, mata bor komposit gigi kecil, mata bor komposit biasa |

| Tingkat 2 (Batu Lepas) | Jenis Huangshi/Hongshi/Tanah Gambut/Tanah Berpasir/Kaolin | 8 jt/jam, 2,4 jt/p | Mata bor paduan, mata bor komposit gigi kecil, mata bor komposit biasa |

| Tingkat 3 (Batu Lunak) | Serpih/Batu Tulis/Batu Penggembalaan/Sekis/Lapisan Pasir Sedikit Disemen Sangat Lapuk | 6 jt/jam, 2 jt/p | Mata bor komposit biasa, mata bor komposit segitiga, mata bor komposit berbentuk roti, mata bor komposit berbentuk pisau |

| Level 4 (Batu Sedikit Lembut) | Serpih, serpih berpasir, serpih minyak, serpih berkarbon, serpih berkapur, lapisan serpih pasir, batu kapur berlempung | 5 jt/jam, 1,7 jt/p | Mata bor komposit biasa, mata bor komposit segitiga, mata bor komposit berbentuk roti, mata bor komposit berbentuk pisau |

| Level 5 (Agak Keras) | Lapisan kerikil dan kerikil, lapisan keruntuhan batu tulis berlumpur, batu tulis hijau klorit serisit, sekis, batu kapur, marmer | 3 juta/jam, 11,50 juta/p | Mata bor komposit biasa, mata bor komposit segitiga, mata bor komposit berbentuk roti, mata bor komposit berbentuk pisau |

| Tingkat 6-7 (Batu Keras Sedang) | Klorit, mika, batu tulis, batu Qianmu, sekis, batu kapur silikat, kalsit | 2 juta/jam, 1,3 juta/P-1,1 juta/P | Mata bor komposit berbentuk pisau, mata bor komposit diperkuat, mata bor komposit gigi helm, mata bor berlian berlapis bermutu tinggi |

| Tingkat 8-9 (Batu Keras) | Batuan mika silikat, gneiss, basal, diorit, piroksenit, kuarsa porfiri Anshan | 1,2 juta/jam, 0,3 juta/P-0,65 juta/P | Mata bor komposit tebal, mata bor komposit berbentuk bilah, mata bor komposit gigi helm, mata bor berlian berlapis listrik konvensional, mata bor berlian polikristalin (TSP) yang stabil secara termal |

| Tingkat 10-11 (Batu Sangat Keras) | Granit, granodiorit, gneiss, riolit, kuarsit | 0,8 juta/jam, 0,5 juta/P-0,32 juta/P | Mata bor sinter badan, mata bor berlian berlapis listrik tingkat rendah, mata bor berlian polikristalin (TSP) yang stabil secara termal. |

| Level 12 (Sangat Hard Rock) | Kuarsit, jasper, serpih sudut, batuan korundum, kuarsa, batu api, jasper | 0,3 juta/jam, 0,16 juta/p | Mata bor sinter badan, mata bor berlian berlapis listrik tingkat rendah, mata bor berlian polikristalin (TSP) yang stabil secara termal. |

Jika Anda memiliki pertanyaan, Anda dapat menghubungi kami melalui obrolan online!

Berbincanglah dengan kamiAnda Mungkin Juga Menyukainya

Example product title

- $1.00

- $1.00

- Unit price

- per

Example product title

- $1.00

- $1.00

- Unit price

- per

Example product title

- $1.00

- $1.00

- Unit price

- per

Example product title

- $1.00

- $1.00

- Unit price

- per

- Choosing a selection results in a full page refresh.