Best Practices for Using Composite Sheet Drill Bits

1. During normal operations, it is strictly forbidden to suddenly reverse the direction of operation to prevent the detachment of the composite sheet drill bits.

2. Ensure that there are no air leaks in the main airway of the air compressor during normal operations to maintain sufficient airflow and pressure, thereby extending the life of the diamond composite sheet drill bits.

3. When using a new composite sheet drill bit for the first time, operate at low speed for half an hour for running-in before progressively transitioning to normal usage.

4. In adverse geological conditions, reduce the axial pressure and rotation speed to prevent drill bit fracture.

5. During normal drilling operations, if it becomes necessary to change the drill bit midway, thoroughly check the borehole for debris. Only proceed with a new composite sheet drill bit if the borehole is clean.

6. To ensure stable and normal operation of the drill bit, replace the stabilizer regularly.

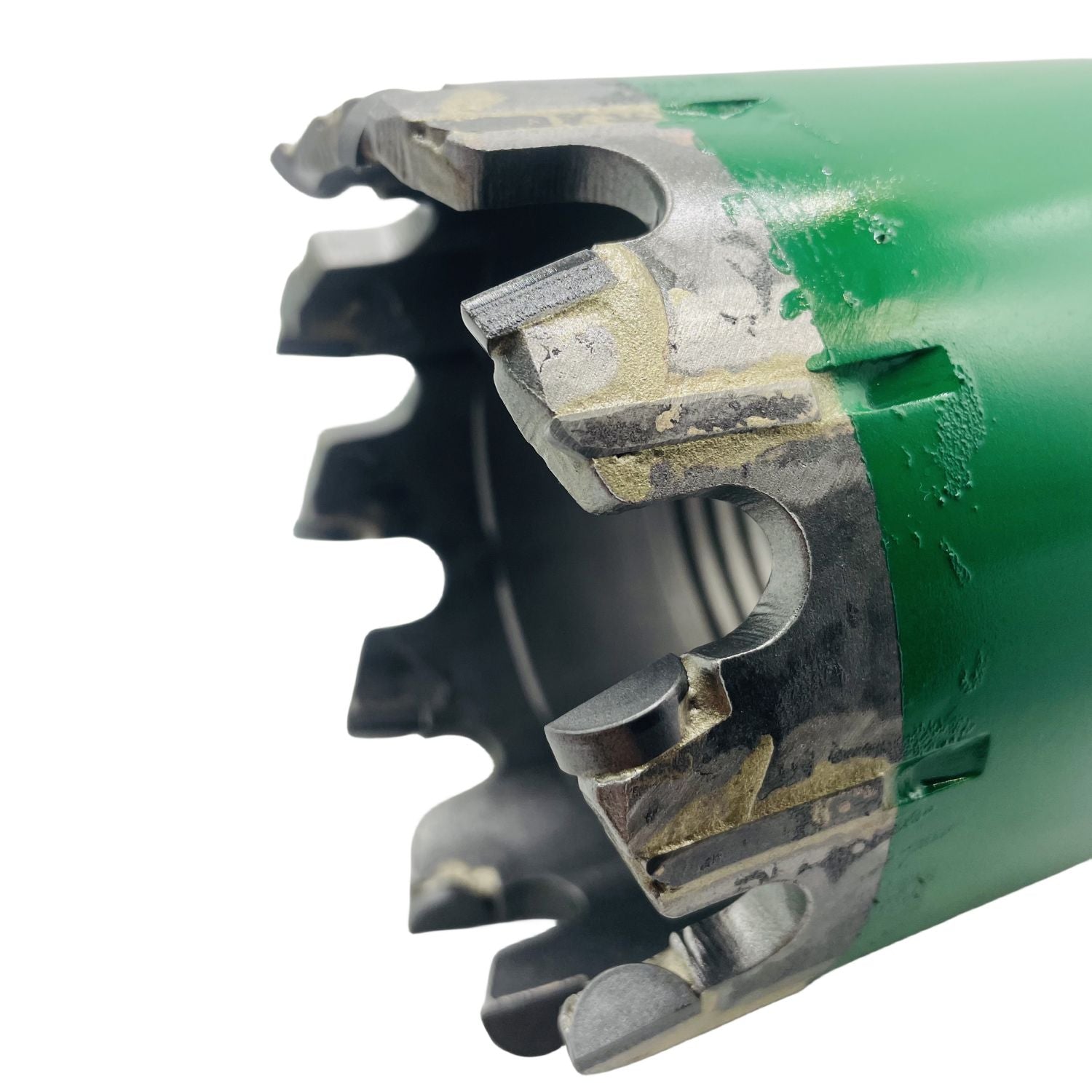

Pay attention to the cleanliness of the drilling area when using a new composite sheet drill bit for the first time to prevent debris from affecting

7. normal operation. Before replacing with a new drill bit, carefully check that the threads and teeth are intact and gently push to test if there are any issues.

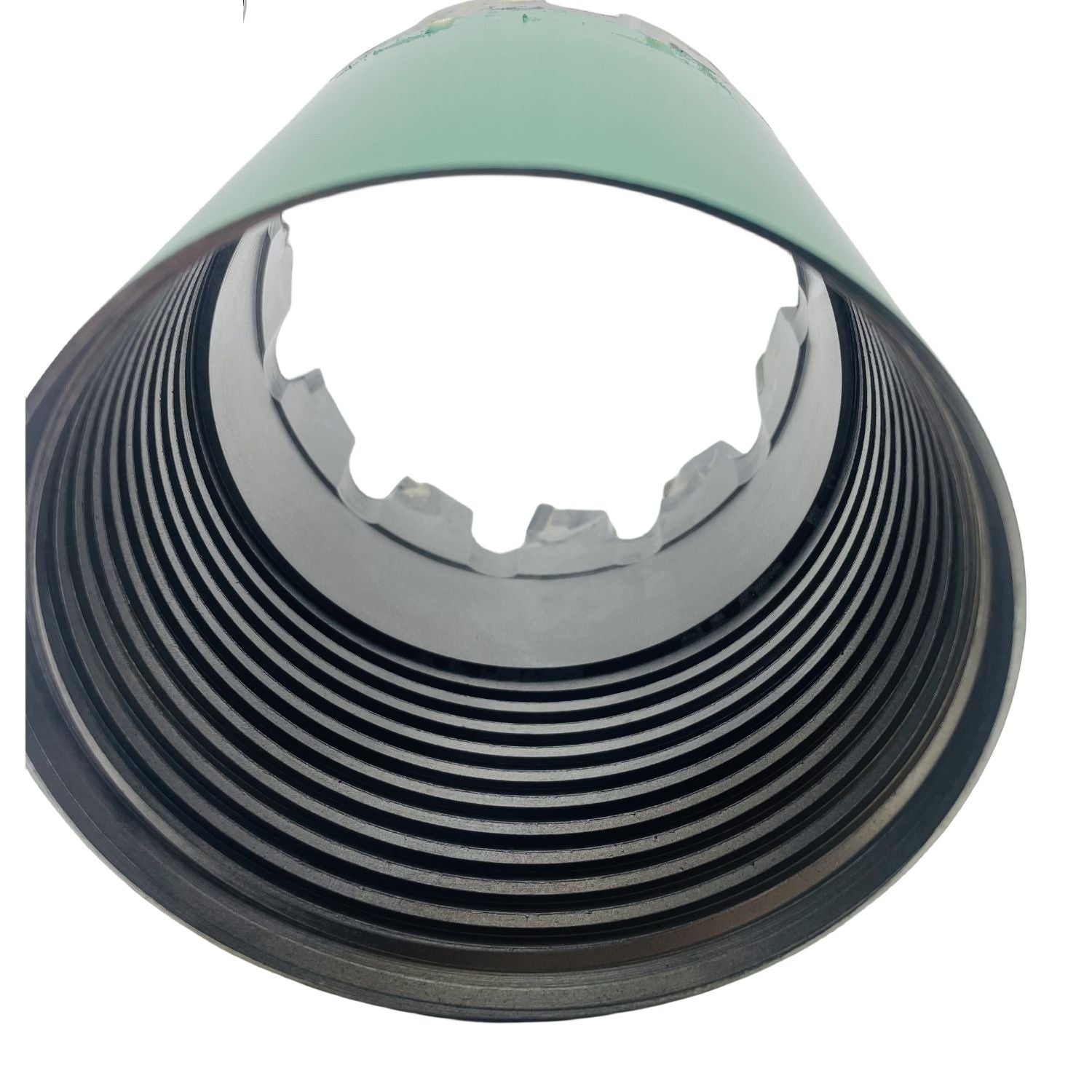

8. Ensure that the inside is dust-free and the air outlet is clear, the threads are lubricated, and after connecting the drill bit with lifting and rotation, you may proceed to use it.

9. It is strictly prohibited to use bent drill rods to avoid uneven stress on the drill bit, which could accelerate damage and affect the normal usage time.

10. Choose different drill bits and operation methods based on different situations.

11. Before descending the well with a composite sheet drill bit, carefully inspect all parts to ensure there are no issues before beginning to use the drill bit.