Performance of PDC Drill Bits in Different Formations

Drilling Technology Li Xiaohuan

Application Scenarios and Suitability of PDC Drill Bits

Drilling Technology Li Xiaohuan

The Advantages and Selection of PDC Drill Bits

Drilling Technology Li Xiaohuan

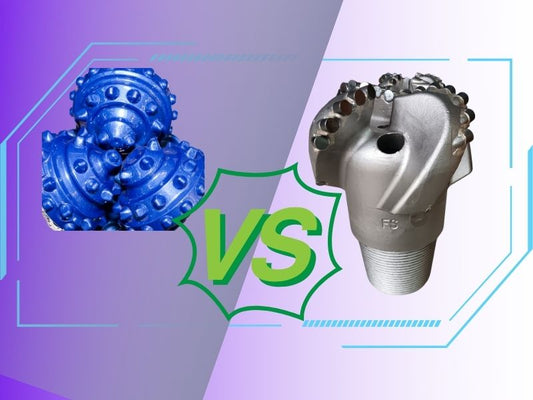

Comparative Analysis of Drill Bits

Drilling Technology Li Xiaohuan

Technological Advances and Future Trends in PDC Drill Bits

Drilling Technology Li Xiaohuan

Latest Technologies and Future Trends in PDC Drill Bits

Drilling Technology Li Xiaohuan

PDC Drill Bits: Applications and Case Studies

Drilling Technology Li Zhongyong

Maintenance and Selection of PDC Drill Bits

Drilling Technology Li Xiaohuan

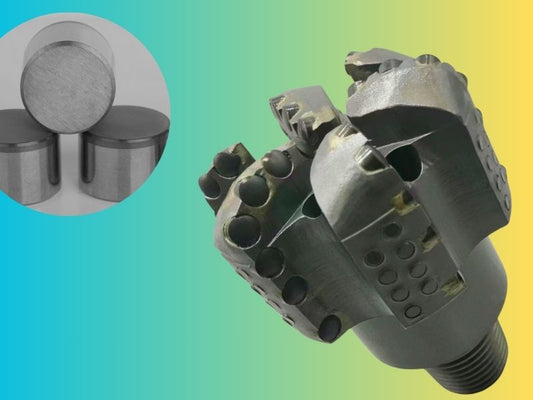

Technical Details and Mechanisms of PDC Drill Bits

Drilling Technology Li Xiaohuan

Performance and Application of PDC Drill Bits

Drilling Technology Li Xiaohuan