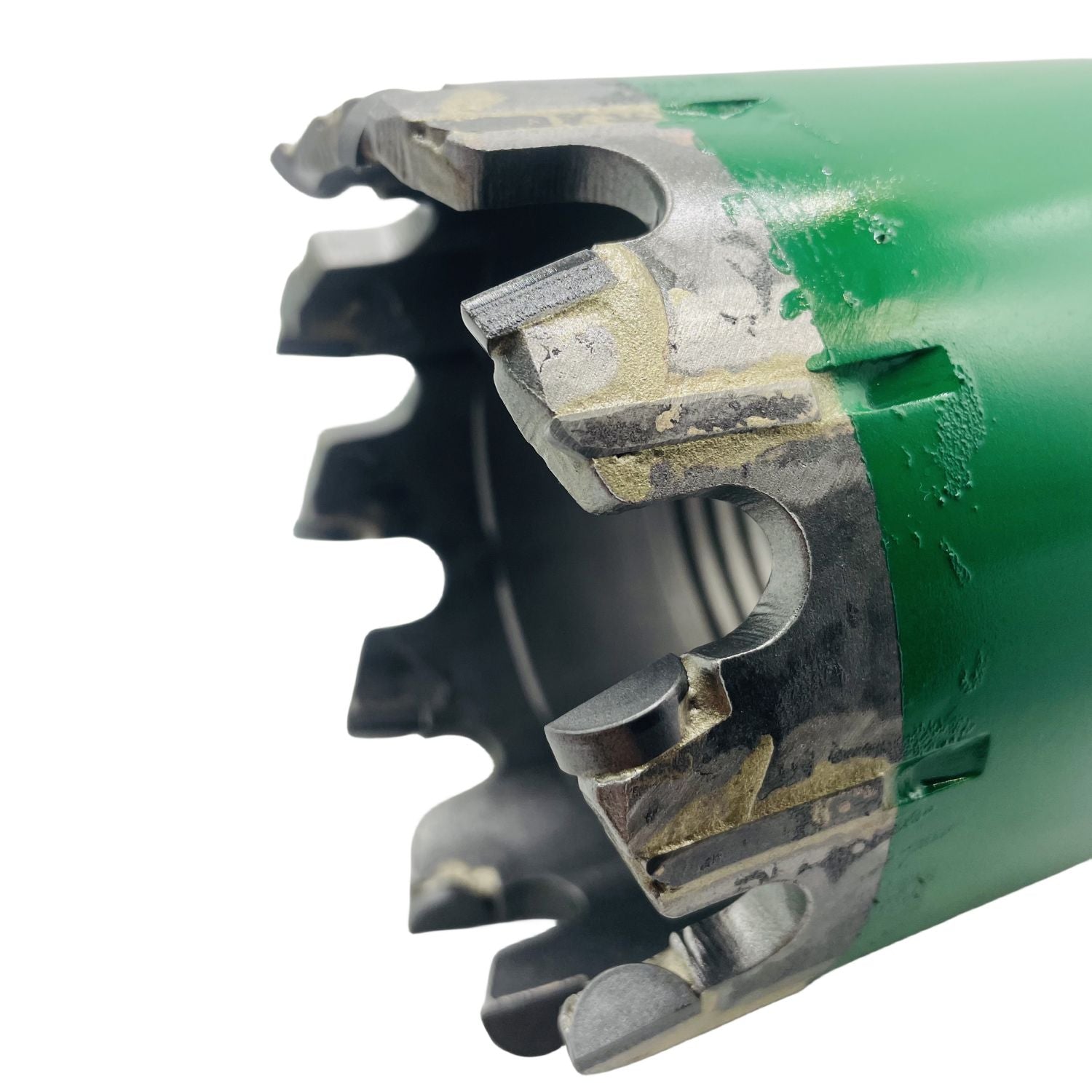

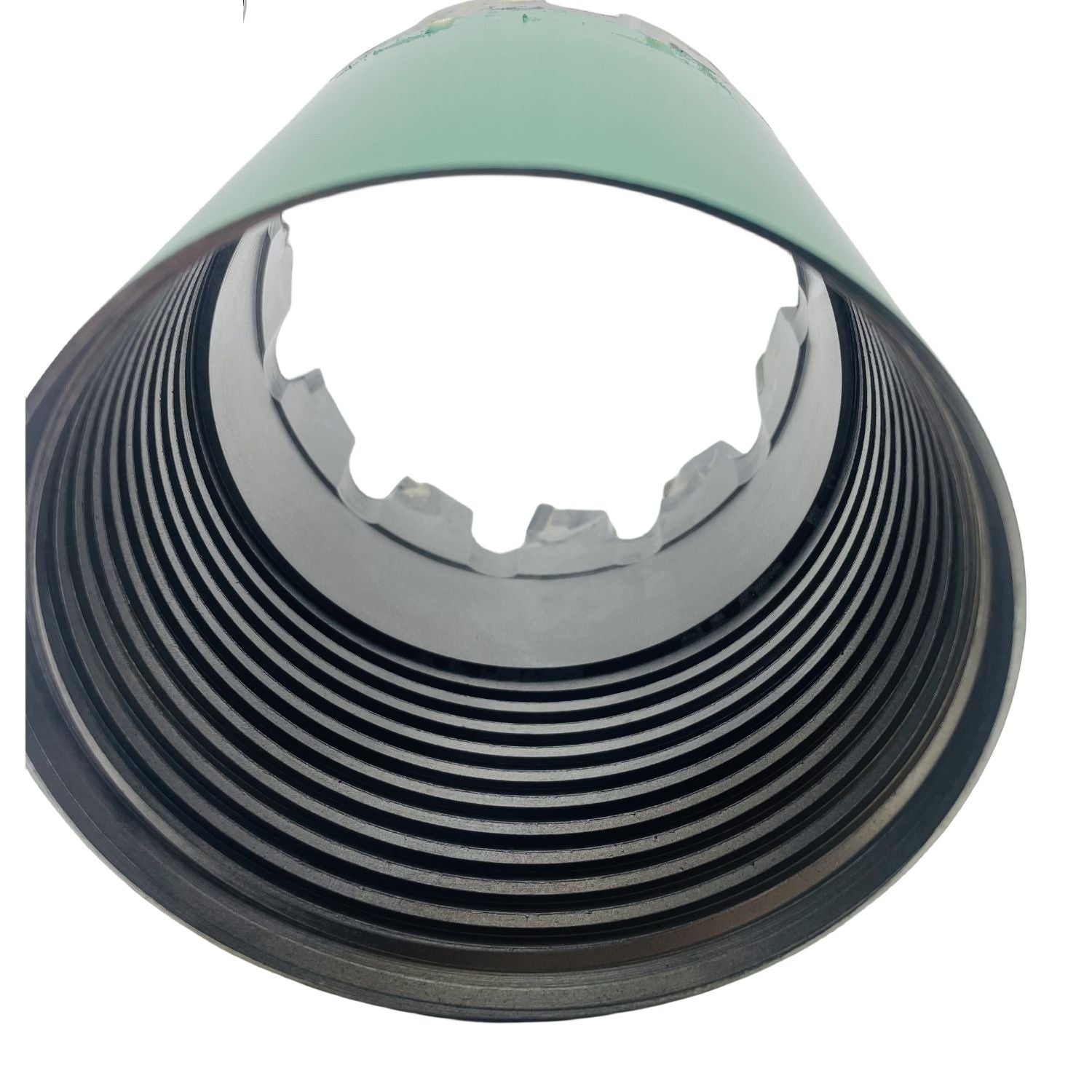

PDC-Kernbohrer mit Klingen-Segmenten für Hartgestein und Granit

Der PDC Kernbohrer mit Klingensegmenten ist für präzises Bohren in hartem Gestein und Granit ausgelegt. Mit langlebigem polykristallinem Diamantmaterial und Klingensegmenten reduziert dieser Bohrer den Verschleiß und verbessert die Schnittleistung....

Unsere Handwerkskunst

| Model | ** |

|---|---|

| Brand | FENGSU |

| Type | Drill bit |

| Material | Aolly |

| Size Range | ** |

| Thread Type | ** |

| Recommended Formation | ** |

| Origin | HUNAN,China |

| Packaging | Carton or Wooden Box |

Umfassende Referenztabelle für Gesteinsbohrungen

| Schichtklassifizierung/-name | Darstellung von Gesteinsschichten | Theoretische Bohrgeschwindigkeit/empfohlene Auszugslänge | Empfohlene Bohrer |

|---|---|---|---|

| Stufe 1 (lockerer Boden) | Sekundärer Löss, sekundärer Hongshi, weicher Sand ohne Kies und eckiger Kies, Kieselgur | 15 Mio./h, 15 Mio./P | Legierungsbohrer, Kleinzahn-Verbundbohrer, gewöhnlicher Verbundbohrer |

| Level 2 (Lockergestein) | Typ Huangshi/Hongshi/Torfiger Ton/Sandiger Boden/Kaolin | 8 M/h, 2,4 M/P | Legierungsbohrer, Kleinzahn-Verbundbohrer, gewöhnlicher Verbundbohrer |

| Stufe 3 (Soft Rock) | Stark verwitterter Schiefer/Schiefer/grasendes Gestein/Schiefer/leicht zementierte Sandschicht | 6 M/h, 2 M/P | Gewöhnlicher Verbundbohrer, dreieckiger Verbundbohrer, brotförmiger Verbundbohrer, klingenförmiger Verbundbohrer |

| Level 4 (Leicht sanfter Rock) | Schiefer, Sandschiefer, Ölschiefer, Kohlenstoffschiefer, Kalkschiefer, Sandschieferzwischenschicht, Tonkalkstein | 5 Mio./h, 1,7 Mio./P | Gewöhnlicher Verbundbohrer, dreieckiger Verbundbohrer, brotförmiger Verbundbohrer, klingenförmiger Verbundbohrer |

| Level 5 (Leicht Hardrock) | Kies- und Kiesschichten, Einsturzschicht aus schlammigem Schiefer, Sericit-Chlorit-Grünsteinschiefer, Schiefer, Kalkstein, Marmor | 3 Mio./h, 11,50 Mio./P | Gewöhnlicher Verbundbohrer, dreieckiger Verbundbohrer, brotförmiger Verbundbohrer, klingenförmiger Verbundbohrer |

| Level 6-7 (mittlerer Hardrock) | Chlorit, Glimmer, Schiefer, Qianmu-Gestein, Schiefer, verkieselter Kalkstein, Calcit | 2 M/h, 1,3 M/P-1,1 M/P | Klingenförmiger Verbundbohrer, verstärkter Verbundbohrer, Helmzahn-Verbundbohrer, hochwertiger galvanisierter Diamantbohrer |

| Level 8-9 (Hard Rock) | Verkieseltes Glimmergestein, Gneis, Basalt, Diorit, Pyroxenit, Quarz-Anshan-Porphyr | 1,2 M/h, 0,3 M/P-0,65 M/P | Verdickter Verbundbohrer, klingenförmiger Verbundbohrer, Helmzahn-Verbundbohrer, herkömmlicher galvanisierter Diamantbohrer, thermisch stabiler polykristalliner Diamant (TSP) Bohrer |

| Level 10-11 (Sehr Hardrock) | Granit, Granodiorit, Gneis, Rhyolith, Quarzit | 0,8 M/h, 0,5 M/P-0,32 M/P | Körpergesinterter Bohrer, niedrig galvanisierter Diamantbohrer, thermisch stabiler polykristalliner Diamant (TSP) Bohrer. |

| Level 12 (Extrem Hard Rock) | Quarzit, Jaspis, Winkelschiefer, Korundgestein, Quarz, Feuerstein, Jaspis | 0,3 M/h, 0,16 M/P | Körpergesinterter Bohrer, niedrig galvanisierter Diamantbohrer, thermisch stabiler polykristalliner Diamant (TSP) Bohrer. |

Wenn Sie Fragen haben, können Sie uns per Online-Chat kontaktieren!

Chatte mit unsSie können auch mögen

Beispielprodukt-Titel

- $1.00

- $1.00

- Stückpreis

- pro

Beispielprodukt-Titel

- $1.00

- $1.00

- Stückpreis

- pro

Beispielprodukt-Titel

- $1.00

- $1.00

- Stückpreis

- pro

Beispielprodukt-Titel

- $1.00

- $1.00

- Stückpreis

- pro

- Die Auswahl einer Option führt zu einem vollständigen Seitenaktualisierung.