brocas sin núcleo cóncavas de tres alas de acero aleado PDC, adecuadas para agujeros de inyección en pozos de agua, exploración geotérmica, minas de carbón

La broca de línea recta cóncava está diseñada para una perforación rápida y sin obstrucciones, mayor durabilidad y perforaciones rectas precisas sin desviaciones.

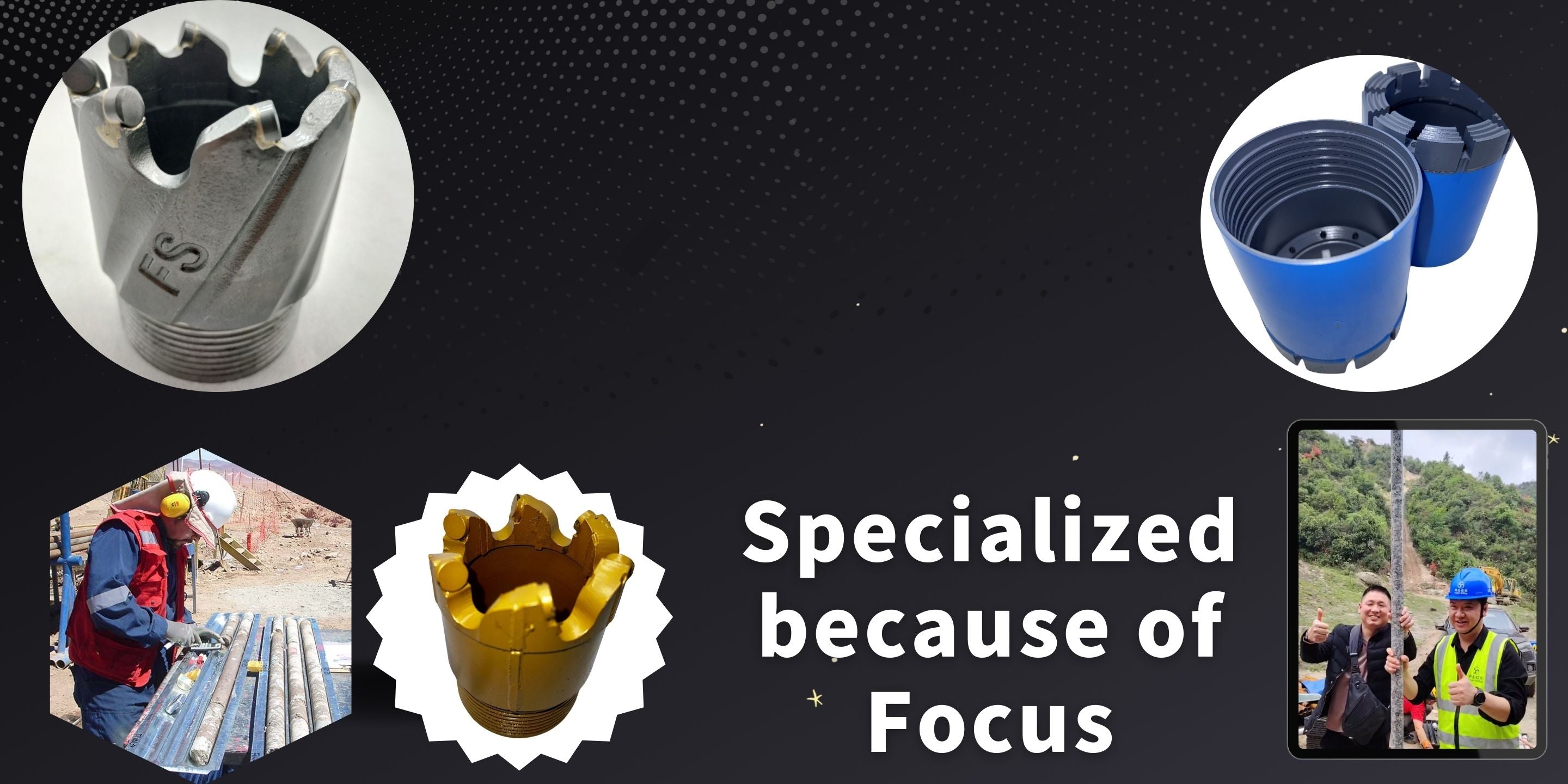

Nuestra artesanía

| Model | ** |

|---|---|

| Brand | FENGSU |

| Type | Drill bit |

| Material | Aolly |

| Size Range | ** |

| Thread Type | ** |

| Recommended Formation | ** |

| Origin | HUNAN,China |

| Packaging | Carton or Wooden Box |

Tabla de referencia completa de perforación de rocas

| Clasificación/Nombre del estrato | Representando estratos de roca | Velocidad de perforación teórica/longitud de extracción recomendada | Brocas recomendadas |

|---|---|---|---|

| Nivel 1 (suelo suelto) | Loess secundario, Hongshi secundario, arena blanda sin grava y grava angular, tierra de diatomeas | 15M/h, 15M/P | Broca de aleación, broca compuesta de dientes pequeños, broca compuesta ordinaria |

| Nivel 2 (Roca suelta) | Huangshi/Hongshi/arcilla turbosa/suelo arenoso/tipo caolín | 8M/h, 2,4M/P | Broca de aleación, broca compuesta de dientes pequeños, broca compuesta ordinaria |

| Nivel 3 (roca blanda) | Esquisto/pizarra/roca de pastoreo/esquisto/capa de arena ligeramente cementada fuertemente erosionada | 6M/h, 2M/P | Broca compuesta ordinaria, broca compuesta triangular, broca compuesta en forma de pan, broca compuesta en forma de hoja |

| Nivel 4 (Roca ligeramente blanda) | Esquisto, esquisto arenoso, esquisto bituminoso, esquisto carbonoso, esquisto calcáreo, capa intermedia de esquisto arenoso, piedra caliza arcillosa | 5M/h, 1,7M/P | Broca compuesta ordinaria, broca compuesta triangular, broca compuesta en forma de pan, broca compuesta en forma de hoja |

| Nivel 5 (Roca ligeramente dura) | Grava y capas de grava, capa de colapso de pizarra fangosa, pizarra de piedra verde de clorita de sericita, esquisto, piedra caliza, mármol | 3M/h, 11,50M/P | Broca compuesta ordinaria, broca compuesta triangular, broca compuesta en forma de pan, broca compuesta en forma de hoja |

| Nivel 6-7 (roca media dura) | Clorita, mica, pizarra, roca Qianmu, esquisto, piedra caliza silicificada, calcita | 2M/h, 1,3M/P-1,1M/P | Broca compuesta en forma de hoja, broca compuesta reforzada, broca compuesta con dientes de casco, broca de diamante galvanizada de alta calidad |

| Nivel 8-9 (rock duro) | Roca de mica silicificada, gneis, basalto, diorita, piroxenita, cuarzo, pórfido de Anshan | 1,2 M/h, 0,3 M/P-0,65 M/P | Broca compuesta engrosada, broca compuesta en forma de hoja, broca compuesta con dientes de casco, broca de diamante galvanizada convencional, broca de diamante policristalino térmicamente estable (TSP) |

| Nivel 10-11 (rock muy duro) | Granito, granodiorita, gneis, riolita, cuarcita | 0,8M/h, 0,5M/P-0,32M/P | Broca sinterizada de cuerpo, broca de diamante galvanizada de bajo grado, broca de diamante policristalino (TSP) térmicamente estable. |

| Nivel 12 (Roca extremadamente dura) | Cuarcita, jaspe, esquisto angular, corindón, cuarzo, pedernal, jaspe | 0,3 M/h, 0,16 M/P | Broca sinterizada de cuerpo, broca de diamante galvanizada de bajo grado, broca de diamante policristalino (TSP) térmicamente estable. |

Si tiene alguna pregunta, puede contactarnos a través del chat en línea!

Habla con nosotrosTambién te puede interesar

Título de producto de ejemplo

- $1.00

- $1.00

- Precio unitario

- por

Título de producto de ejemplo

- $1.00

- $1.00

- Precio unitario

- por

Título de producto de ejemplo

- $1.00

- $1.00

- Precio unitario

- por

Título de producto de ejemplo

- $1.00

- $1.00

- Precio unitario

- por

- Elegir una selección resulta en una actualización completa de la página.